Spray Drying

Spray Dryer Technology at Elan Technology

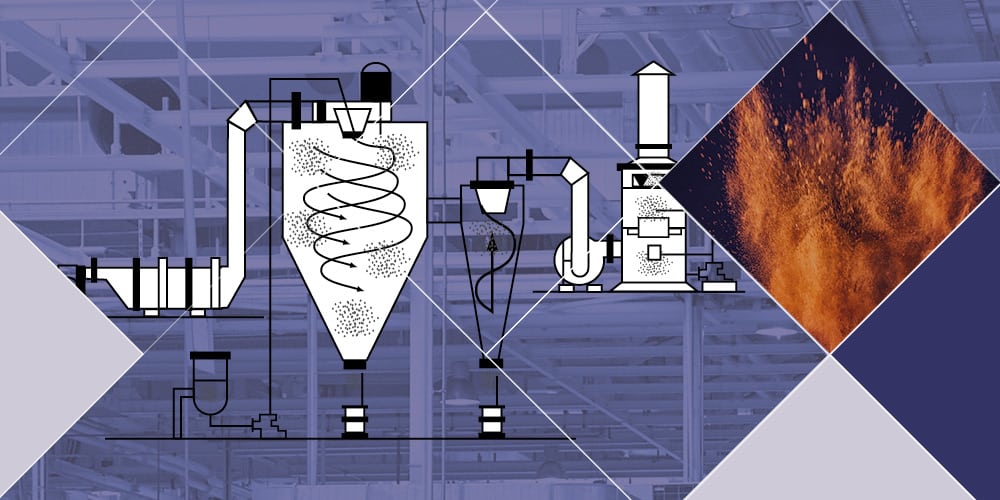

Spray dryer technology allows various materials to be combined and then processed into a homogeneous, free-flowing powder. Many materials are spray dried simply to produce a dust-free powder. However, in many cases, such as catalysts, close control of the particle size distribution is required in order to ensure proper performance of the final material.

Spray drying is a process used to produce dry granular powders from a slurry, which is a mixture of liquid solution and solid materials. Production of powders is accomplished by rapidly drying the slurry using heated air. The slurry is introduced into the hot air stream via a rotating atomizer wheel or nozzles. While both methods produce granular product, the atomizer wheel provides a broader particle size distribution. Each method allows for very consistent control of the particle size distribution.

During Elan’s spray drying process, operating conditions such as temperature, wheel speed (if applicable) and pump pressure are closely monitored to ensure consistent product quality. In-process quality control can be tailored to the requirements of each specific customer. However, we typically monitor particle size distribution, moisture content, and bulk density.

Although a variety of liquids can be used to form the slurry, Elan Technology primarily processes aqueous based mixtures. We have the capability to prepare slurries onsite or we can accept bulk tankers of pre-mixed material. Specific batching instructions for toll spray drying are developed for each customer’s materials based on their individual requirements.

Post-spray dying, materials can be screened to further refine the particle size distribution and then packaged in customer specified containers.

Spray Drying Services Frequently Asked Questions

What is spray drying?

Spray drying is a process that converts a liquid feed into a dry powder. This is achieved by atomizing the liquid into a fine mist and then drying it rapidly in a hot gas stream. The result is a fine, uniform powder that retains the original properties of the liquid.

What types of atomization are available?

Depending on the project requirements, we have rotary wheels, high pressure nozzles or two fluid nozzles available.

What types of products can you spray dry?

We process a wide variety of industrial materials (catalysts, pigments, ceramics, etc.). However, we do not process food products or solvent based solutions.

How does spray drying compare to other drying methods?

Spray drying is desirable for its ability to produce uniform, high-quality powders with controlled particle sizes. It is also faster and more efficient compared to methods like freeze-drying or air-drying, especially for heat-sensitive materials.

What is the typical particle size of spray-dried powders?

Particle size can vary depending on the feed and process conditions but generally ranges from 10 to 150 microns. Various particle sizes can be achieved through adjustments in the process parameters.

What are the important factors to consider when choosing a spray drying service?

- Feed Characteristics: Type and properties of the liquid feed.

- Desired Powder Properties: Particle size, moisture content, and bulk density.

- Production Capacity: Scale of production required.

- Quality Control: Standards and testing procedures.

- Experience and Expertise: Technical capabilities and industry experience of the service provider.

What are the typical lead times for spray drying projects?

Lead times can vary based on project complexity and scale. Generally, it ranges from a few weeks to several months. Pleasecontact us with your specific requirements for a more accurate timeline.

What quality assurance measures are in place during spray drying?

Typical properties monitored during spray drying are particle size, moisture content, and bulk density. However, we can provide monitoring for additional specifications if required.

Can you handle small-scale or pilot projects?

Yes, we offer pilot spray drying services to help you develop and test formulations before scaling up to full production.

How do I get a quote for spray drying services?

To receive a quote, pleasecontact us

What should I include in my initial inquiry?

When reaching out, please include:

- Particle size requirements

- Anticipated project volume, are listed volumes in spray dried form or slurry?

- Desired operating temperatures, if known

- Batching process requirements/ slurry preparation